Views: 53 Author: Site Editor Publish Time: 2022-05-11 Origin: Site

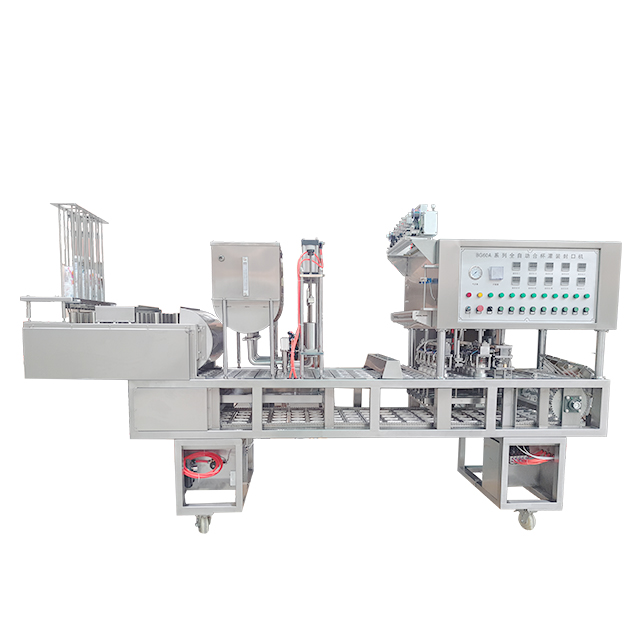

Automatic cup filling sealing machine can use programmable logic controller, pneumatic control components, intelligent digital temperature control system, and has the characteristics of high sealing strength, good sealing performance and low failure rate. It is a good product for automatic production of enterprises. According to customer requirements, it can be Customized machines with special specifications.

How to use Automatic cup filling sealing machine correctly?

Why choose Automatic cup filling sealing machine?

What are the structural features of the Automatic cup filling sealing machine?

1. During the working process of the Automatic cup filling sealing machine, the surface of the induction head should be touched frequently to check whether it is overheated. If it is found that the hand is hot, the heating should be stopped, and it should be cooled before starting work (the power supply can be turned off for cooling), and the "WARMUP" green indicator light When it is off, do not press the start button to avoid false triggering. After the machine is finished working, please turn off the power switch on the panel.

2. The Automatic cup filling sealing machine is equipped with a fuse of 5A, which cannot be replaced by a fuse larger than 5A.

3. There is high voltage inside, and the bottom plate is electrified. It is strictly forbidden to repair it without permission to avoid personal electric shock.

4. Stop using the Automatic cup filling sealing machine if any exposed wires are found before use, and can only be used after maintenance.

5. The Automatic cup filling sealing machine should not be impacted, pressed or damp during transportation, storage and use.

Automatic cup filling and sealing machine is suitable for filling all kinds of square, round and cans, wide-mouth bottles and plastic beverage bottles; the exposed parts of the whole machine are made of stainless steel and engineering plastics, and all parts in contact with liquid are made of stainless steel.

The bottle holder follows the principle of accurate and fast filling, and uses an elastic structure without bottle leakage; the wine tank and liquid level use a three-point liquid level automatic control device, and the wine inlet pipeline uses a stainless steel imported solenoid valve;

The vacuum system of the Automatic cup filling sealing machine can be installed under the workbench and does not use circulating water.

Automatic cup filling sealing machine is a packaging equipment specially designed for cups, boxes, bowls, shaped containers, etc. It has the advantages of simple operation, stable performance and easy maintenance. It can be used as a stand-alone machine or connected to a production line. The machine adopts automatic program control, beautiful appearance, reasonable structure, complete functions, easy operation, conforms to the requirements of the national health law, and meets the standard and large-scale production. Stable performance, high production efficiency and easy operation.

Would you like to order Automatic cup filling and sealing machine against this background? If necessary, you can contact ZHEJIANG HONGZHAN PACKING MACHINERY CO., LTD You will supply the Automatic cup filling and sealing machine of the best quality.